Simon Thomas

14 Dec 2025

Trex Custom Curve: A Practical Guide to Curved Trex Decking

If you have ever looked at a curved deck edge and thought, “That looks expensive and hard to build”, you are not alone. Most decking is built in straight lines because timber and deck boards are easy to cut square. Curves feel like a step up.

That is where Trex Custom Curve comes in. It is a way to create curved Trex decking that looks smooth, modern, and made for the space. A custom curved edge can make a garden feel bigger, soften harsh lines, and turn a basic rectangle into an outdoor space that feels designed, not just built.

In this guide, I will explain what Trex Custom Curve is, how it works, where curved Trex decking makes sense, and what you need to plan before you order anything. I will also share design ideas, common mistakes, and simple tips that help curved composite decking last.

What is Trex Custom Curve?

Trex Custom Curve is a process that forms Trex composite decking into curved shapes. Instead of forcing straight deck boards to follow a curve, the boards are shaped to match a planned radius. This is usually done using controlled heat and forming methods so the board bends cleanly and keeps its shape.

It is not the same as trying to bend a board on site with brute force. Composite decking needs the right approach, or it can kink, twist, or look uneven. With a custom curved solution, the curve is planned, made to spec, then installed as part of the deck layout.

When people say “Trex custom curve”, they often mean one of these features:

A curved deck edge (the front of the deck sweeps in an arc)

Curved trex decking used as a picture frame border

A curved step front or curved stair tread

Curved fascia and rim boards to match the deck edge

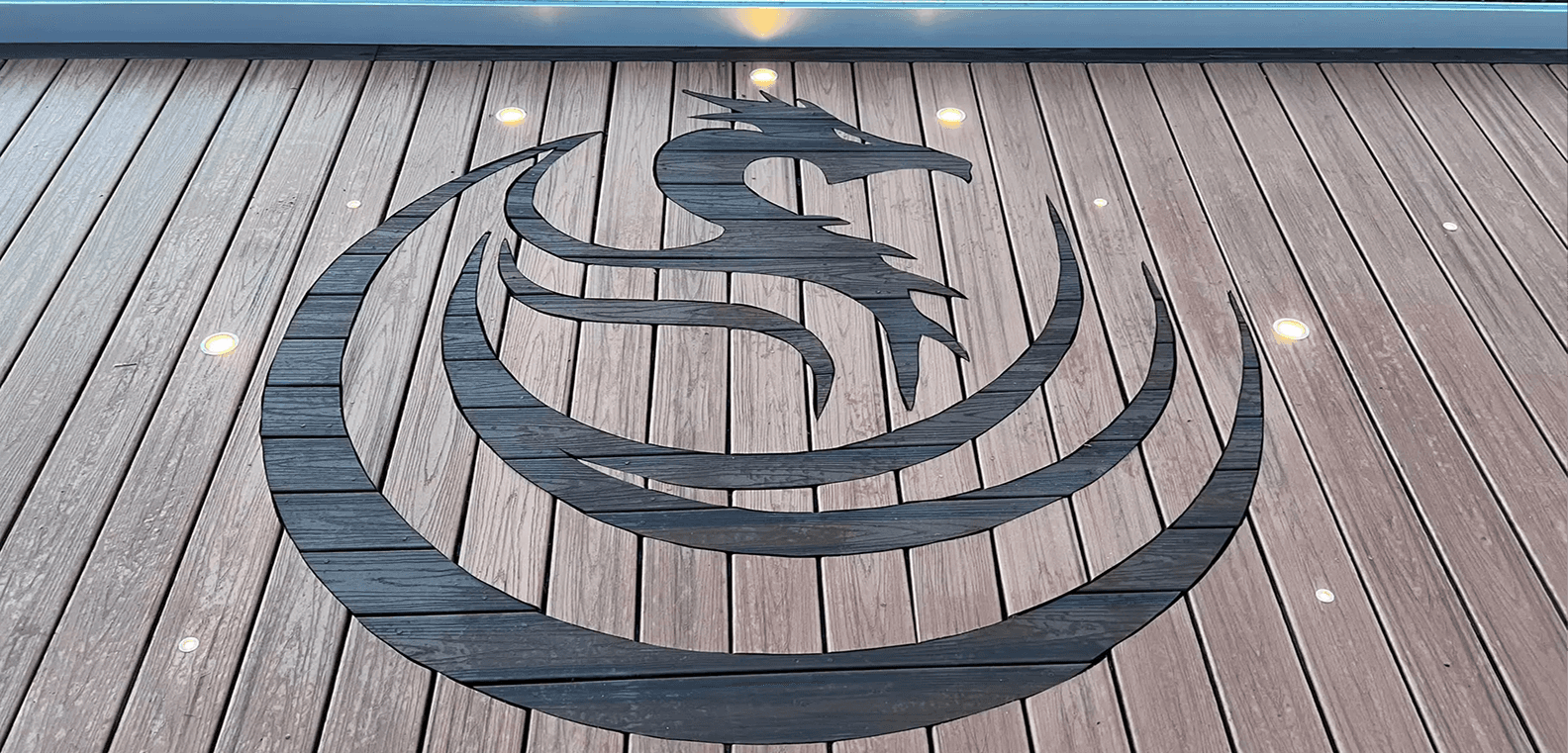

Curved inlays that create patterns on the deck surface

Done well, it looks high end. Done poorly, it can look wobbly or unfinished. The planning is what makes the difference.

Why curved decking is so popular right now

Straight decks work. They are simple and practical. But curves change the feel of an outdoor space.

A curved deck can:

Soften the look of fences, walls, and straight patios

Make a deck feel more natural in a garden with plants and lawns

Create a better flow from doors to seating areas

Help frame a hot tub, fire pit, or dining area

Add “wow” without needing a massive footprint

Curves also help when the house or garden is not perfectly square. Many gardens have angles, slopes, or odd corners. A curved trex decking edge can make those shapes feel intentional.

Which Trex boards can be used for custom curved work?

Many homeowners ask this first, and it is a smart question. Not every product behaves the same when shaped. Trex composite boards come in different lines, colours, and profiles, and availability can vary depending on where you are buying.

A term you will often see is Trex Transcend. Trex Transcend is one of the premium ranges people choose when they want a richer grain look and strong surface performance. It is commonly used for showpiece builds where the decking is a main feature, not just a platform.

When you plan a Trex Custom Curve project, you want all the visible parts to match. That includes the deck boards, any fascia, and any border boards used to create a clean finish.

My practical advice is simple: choose your Trex composite range and colour first, then plan the curve around the board system, not the other way round.

Curved deck design ideas that look great in real gardens

Here are a few curved deck layouts that work well and do not feel over designed.

Curved front edge with straight board runs

This is one of the most popular options. The main deck boards run straight from the house outward, but the front edge is custom curved. It looks clean and keeps installation simple because most boards are still straight.

Full curved picture frame border

A picture frame border is a neat rim of boards that goes around the deck to “frame” it. With Trex custom curve, that border can follow an arc. It looks very polished, especially when paired with matching fascia.

Curved steps

Curved steps are a big upgrade in feel. Even one wide curved step can make a deck feel like a proper outdoor room. It also helps with traffic flow because the entry point feels wider.

Curved deck around a feature

This works well around a tree, a hot tub base, a pergola post layout, or a fire pit area. The curve helps the deck feel built around the garden, not dropped on top of it.

Mixed shapes for tricky gardens

Some gardens are narrow with a wider end, or they have angled boundaries. A custom curved edge can balance the shape and make the outdoor space feel more even.

Planning a Trex Custom Curve project the right way

Curves look simple, but they are not guesswork. Before you order any custom curved parts, get these basics sorted.

1. Decide what is being curved

Are you curving the deck edge only, or also the border, fascia, and steps? The more parts you curve, the more important accuracy becomes.

2. Know your curve size

A gentle curve is easier and often looks better than a tight curve. Tight curves can look forced, and they may need more pieces, more joints, and more framing.

3. Make sure the frame supports the curve

Curved deck boards still need strong support underneath. If the frame is not built to match, the curve can look lumpy. This is where many curved deck projects fail.

The rim joist, noggins, and edge blocking matter a lot here. You want the edge to feel solid when you walk near it.

4. Plan drainage and airflow

In wet climates, a deck needs to dry out. A curved edge should not trap water or block airflow. Composite decking does well when it is installed with proper gaps and good ventilation.

5. Think about finishing details early

Curved fascia, edge trims, and board ends need a clean plan. A curve makes rough cuts more obvious, so finishing is not an afterthought. It is part of the design.

A simple table: what affects the cost of a curved Trex deck?

Exact prices vary by supplier, region, and deck size, but these are the cost drivers that show up on most jobs.

Cost factor | Why it changes the price | What to do |

|---|---|---|

Curve tightness | Tighter curves often mean more work and more joins | Choose a gentle radius if you can |

Curved steps | Steps need extra framing and finishing | Keep step count practical |

Border and fascia matching | More curved parts means more labour and planning | Decide where the “feature” should be |

Frame complexity | Curves need stronger edge support | Budget for extra timber or aluminium |

Trex composite range | Premium lines like Trex Transcend can cost more | Pick the look you want early |

Site access | Hard access can slow install | Plan delivery and storage space |

Installing curved Trex decking the clean way

If you are hiring a fitter, you still want to understand the basics. If you are doing it yourself, read this twice and go slow.

Start with a perfect edge line

A curved deck looks best when the curve is smooth and consistent. That means you need a true line to build to. Many installers use a template, batten, or marked radius to set out the arc.

Build the frame to the curve

Do not try to force the curve at the last minute. The subframe should support the arc with solid blocking. The edge needs to feel stiff, not springy.

Keep board gaps consistent

Composite decking expands and contracts. Curved trex decking still needs proper spacing at ends and edges. Even small spacing mistakes can stand out on curves.

Treat the curve like a feature

On a straight deck, the eye forgives small variations. On a curved deck, the eye follows the line. That is why neat cuts, matched colours, and clean fascia matter more.

Common mistakes with custom curved composite decking

These are the problems I see most often when people try to build curves without planning.

The curve is set out by eye, so it looks uneven

The rim joist is not supported, so the edge bounces

The fascia does not match the curve, so the finish looks broken

Too many short pieces are used, creating a choppy look

Gaps are inconsistent, so the curve looks messy

Water pools in a low spot because the fall was not planned

A curved deck should feel smooth and intentional. If it feels fussy, it usually needs a simpler curve and a cleaner border plan.

My views: is Trex Custom Curve worth it?

Here is my honest take as someone who cares about finished detail.

Pros

A curved deck looks high end and designed

Curves can make an outdoor space feel softer and more natural

Curved edges work well with lawns, planting, and patios

Trex composite boards give a consistent colour and surface finish

Cons

Curves cost more because the frame and finishing take longer

Tight curves can show joins more clearly

Poor planning is easier to spot on a curve than on a straight edge

You need a fitter who understands composite decking, not just timber

If your garden layout suits it, a custom curved Trex deck can be one of the best upgrades you can make. If your space is small or very square, a simple straight deck with strong details might give better value.

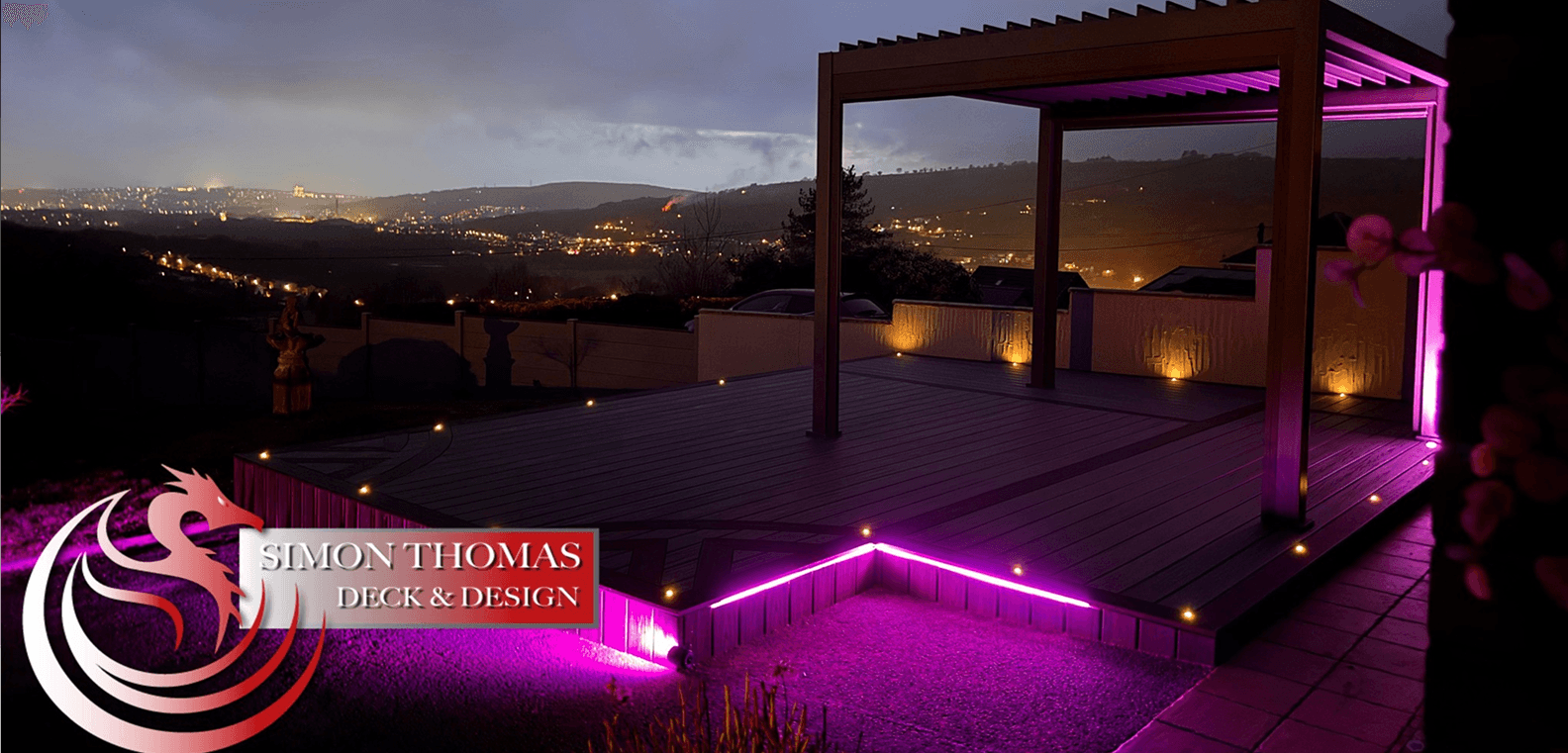

Work with me: Simon Thomas Deck and Design

If you want a curved deck that looks smooth, feels solid, and fits your garden properly, I can help. I am Simon Thomas at Simon Thomas Deck and Design. I design and build composite decking projects, including curved deck edges and custom curved features, with a focus on clean lines and long lasting structure.

If you have an idea in mind, I can help you turn it into a build plan, choose the right deck boards, and create a finish that suits your outdoor space.

Share:

get in touch

ready to build your

dream deck?

Don't let the thought of planning and building overwhelm you. With our expertise, turning your vision into a stunning reality is simple and stress-free. Take the first step toward enjoying your beautiful new deck.